Dr. Shidao Kun, Director of Biotechnology at eSUNMed, was invited to attend the T20+ Conference, where he delivered a keynote speech titled ŌĆ£Innovative Breakthroughs and Future Prospects of Biodegradable Polyester Materials in the High-End Aesthetic Field.ŌĆØ┬ĀIn his presentation, he shared cutting-edge technological achievements and industry development insights.

With the continuous advancement of material synthesis design and processing technologies, biodegradable polyester materials are experiencing significant opportunities in the development of high-end regenerative aesthetic filler products. Following decades of related research in the industry, biodegradable polyester materials such as PLLA, mPEG-PLLA, PDLLA, and PCLŌĆöknown for their high biosafety and effective stimulation of collagen regenerationŌĆöhave become the trend in regenerative facial filler products. These materials are typically processed into microspheres with a particle size distribution of 20ŌĆō50 ╬╝m, uniform (narrow) particle size distribution, and smooth surfaces.

In recent years, regenerative aesthetic filler products have been continuously launched, leading to increasingly fierce market competition. How future regenerative injectable aesthetic fillers can achieve innovation and development is a topic worthy of in-depth exploration.

Characteristics of Biodegradable Polyester Materials

Biodegradable polyester materials are characterized by their wide range of sources, diverse types, high design flexibility, excellent biosafety, and superior processing and mechanical properties. Notably, the strong designability of biodegradable polyester materials allows for performance tuning by reasonably designing monomer compositions, polymer molecular chain structures, condensed phase structures, and heterogeneous morphologies to meet the needs of various medical device applications.

For regenerative aesthetic filler products, more attention is paid to the degradability rate control, hydrophilic/hydrophobic balance, material softness/hardness, in vivo metabolism and biosafety, as well as the advantages of being processed into biodegradable microspheres.

Innovation and Application Insights on Degradable Regenerative Filler Products

1. Regenerative Filler Materials with Specific Degradation Designs

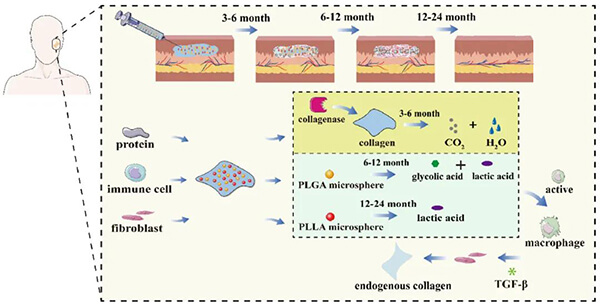

Filler materials are prepared by blending collagen, PLGA, and PLLA microspheres, achieving effects of skin filling or stimulating collagen regeneration at different stagesŌĆöearly, middle, and late phases.[1]

Schematic┬Āillustration of soft tissue augmentation using PLLA/PLGA microspheres/collagen composites [1].

2. Microsphere Filler Materials with Specific Structural Designs

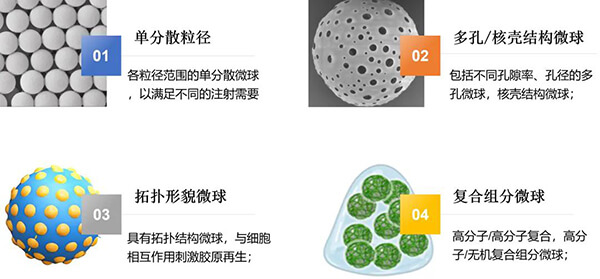

Most currently marketed facial fillers containing biodegradable polyester microspheres feature solid, polydisperse microspheres. Microspheres with monodisperse sizes, porous/core-shell structures, topological morphologies, and composite compositions show potential application value in biodegradable polyester facial filler products.

Design of microspheres with specific structures.

3. Fully Liquid Degradable Regenerative Filler Materials

By copolymerizing hydrophilic polymers with biodegradable polyesters, amphiphilic biodegradable materials can be prepared. Through the rational design of polymer molecular weights and hydrophilic/hydrophobic segment ratios, fully liquid injectable degradable regenerative filler materials can be developed, featuring injectability and uniform filling. GOURI, a fully soluble (liquid) polycaprolactone (PCL) filler developed by Korean company Dexlevo, contains no particles and can be directly injected. It has obtained European CE certification and won the Best Injection Award at the AMWC Awards Ceremony in Monaco. According to related patents, this fully liquid injectable formulation contains amphiphilic polyester materialsŌĆöhydrophilic components derived from polyethylene glycol, and hydrophobic components consisting of biodegradable polyester materials.

GOURI fully liquid PCL filler.

4. Regenerative Filler Products Based on Microneedle-Loaded Biodegradable Microspheres

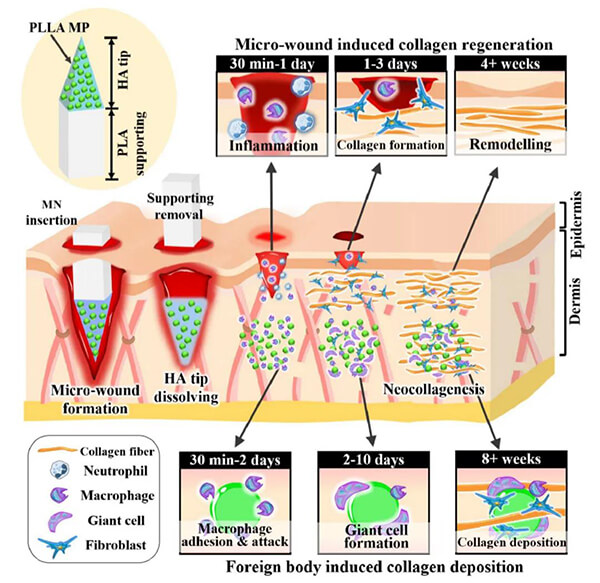

By loading biodegradable polyester microspheres onto microneedle arrays, local overdosing and inflammation can be avoided. This approach yields a milder inflammatory response compared to dermal injections of PLLA microspheres. Microneedle-mediated delivery of PLLA microspheres not only rapidly initiates collagen production during the early treatment phase via micro-injury-induced wound healing cascades, but also induces a foreign body response through the microspheres to continuously stimulate collagen deposition, significantly enhancing neocollagenesis and offering great application value.

Schematic illustration of a composite microneedle (MN) device containing hyaluronic acid (HA) microneedle tips loaded with PLLA microspheres (PLLA MP), supported by a patch for rapid and long-lasting dermal collagen regeneration [2].

5. Application Scenario Innovation

In addition to facial filling applications, regenerative aesthetic filler products hold potential value in areas such as neck filling, abdominal muscle contouring, and leg filling.

Application scenarios for tissue filling in different body regions.

After decades of research and application exploration, the safety and efficacy of biodegradable polyester materials in regenerative aesthetic filler products have been verified. The development of the next generation of products is highly anticipated. The unique advantages of biodegradable polyester materials and microspheres offer ample room for innovation and development in regenerative aesthetic filler products. Innovations such as specific degradation design, special microsphere structural design, fully liquid injectables, microneedle loading, and diversified injection sites have great potential to drive the continued evolution of regenerative aesthetic fillers.

References

1. Li, X., Liao, X., Jia, Z., Liu, S., Li, P., Li, L., Zhang, W., Niu, X. and Fan, Y., 2024. Biodegradable PLLA/PLGA microspheres/collagen composites for continuous soft tissue augmentation. Composites Part B: Engineering, 283, 111603.

2. Chen, M.C., Chang, C.C., Wu, C.L., Chiang, P.M., Yeh, C.C., Chen, Y.H. and Sheu, M.T., 2024. Augmenting dermal collagen synthesis through hyaluronic acid-based microneedle-mediated delivery of poly (l-lactic acid) microspheres. International Journal of Biological Macromolecules, 281, 136311.

3. Goldie, K., Peeters, W., Alghoul, M., Butterwick, K., Casabona, G., Chao, Y.Y.Y., Costa, J., Eviatar, J., Fabi, S.G., Lupo, M. and Sattler, G., 2018. Global consensus guidelines for the injection of diluted and hyperdiluted calcium hydroxylapatite for skin tightening. Dermatologic Surgery, 44, S32-S41.