At the intersection of modern medicine and aesthetics, a material revolution is quietly unfolding. Biodegradable polyester materials, with their unique properties and environmental advantages, have emerged as a powerful driving force behind the innovation and future development of regenerative aesthetic filler products. They are not only redefining the sustainability of beauty but also bringing safer, more natural, and longer-lasting solutions to the industry.

I. Limitations┬Āof Traditional Aesthetic Filler Materials

Reviewing the development of aesthetic filler materialsŌĆöfrom early silicone and hyaluronic acid to the later poly-L-lactic acid (PLLA)ŌĆöeach type has its advantages and disadvantages. Traditional filler materials such as silicone and polyacrylamide hydrogel have long been used for facial contouring and tissue restoration, yet their limitations have increasingly become apparent, restricting their application in modern regenerative aesthetics. The main issues are as follows:

- Insufficient biocompatibility:Non-degradable materials such as silicone can trigger chronic inflammation, foreign-body reactions, or fibrosis, leading to swelling, induration, or infection.

- Non-degradability:Traditional materials like silicone cannot degrade in vivo and may cause tissue aging or functional abnormalities over time.

- Purely filling function:Traditional materials mainly act as physical fillers, lacking the ability to stimulate collagen production or tissue regeneration, resulting in less natural and short-lived effects.

- Limited customization:Standardized filler products are difficult to tailor to individual patient needs, limiting the advancement of precision aesthetics.

II. Performance Advantages of Biodegradable Polyester Materials

Biodegradable polyester materials, such as polylactic acid (PLA), polycaprolactone (PCL), and poly(lactic-co-glycolic acid) (PLGA), exhibit a range of outstanding properties:

(1) Excellent biocompatibility that avoids prolonged inflammation and generates non-toxic degradation products that can be absorbed or excreted;

(2) A degradation timeline consistent with their intended biological function;

(3) Mechanical properties suited to the intended application;

(4) Adequate processability for various designs.

These characteristics are influenced by molecular weight, hydrophilicity/hydrophobicity, surface charge, degradation and erosion mechanisms, among others. By tuning these parameters, materials can be synthesized and designed to optimally match the required biomedical performance specifications.

1. Biocompatibility

Biocompatibility refers to the ability of a material, when in contact with biological tissues, blood, or bodily fluids, to elicit an appropriate host response that enables the material to perform its intended function without causing harmful local or systemic effects.

Biodegradable polyester materials inherently possess good biocompatibility, and their degradation products can be safely metabolized or excreted.

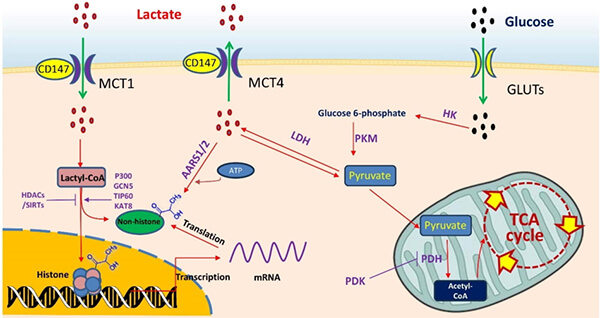

For instance, PLA degrades into lactic acid, a natural metabolic intermediate in the human body, which enters the tricarboxylic acid (TCA) cycle and is ultimately converted into carbon dioxide and water, excreted via respiration or urine [1].

Figure 1: Metabolic transformation of lactic acid in the human body [1]

2. Tunable Degradability

The key to the tunable degradability of biodegradable polyester materials lies in matching their degradation behavior with the rhythm of tissue regeneration.

These materials act as temporary functional scaffolds, whose degradation not only determines their disappearance but also modulates the microenvironment and progression of tissue repair (via surface or bulk erosion).

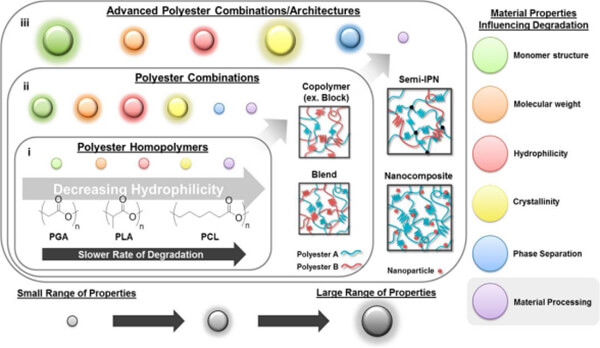

By tuning monomer composition and copolymer ratios, molecular weight, crystallinity and morphology, surface modifications, and even smart-responsive design [2], the degradation period (ranging from weeks to years) can be precisely controlled to match different tissue regeneration ratesŌĆöe.g., 3ŌĆō6 months for superficial skin fillers or 12ŌĆō24 months for deep structural support.

Figure 2: Material characteristics influencing polyester degradation [2]

3. Tunable Mechanical Properties

The clinical suitability of biodegradable materials depends on how well their mechanical performance dynamically matches the target tissue.

Unlike traditional inert implants, biodegradable materials must provide appropriate mechanical support during tissue remodeling while gradually transferring load to new tissue.

This requires that modulus, strength, extensibility, and degradation rate all be spatiotemporally tunable.

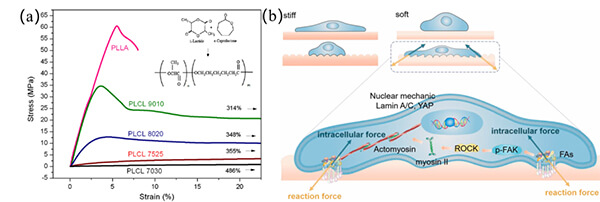

Through monomer selection and sequence design (e.g., PLA/PCL/PGA ratios), chain architecture control (linear, branched, cross-linked), condensed-state manipulation (crystallinity, orientation, phase separation), and heterogeneous network construction (nanocomposites, interpenetrating networks, gradient structures) [3], a broad range of mechanical behaviors can be achievedŌĆöfrom soft, flexible gels suitable for dermal or facial filling [4] to rigid scaffolds for bone contouring.

For example:

- Soft-tissue fillers (fat or dermis replacement) require a low elastic modulus (<1 MPa) and high elongation at break, simulating natural soft-tissue mechanics.

- Structural fillers (jawline or nasal bridge augmentation) require moduli of several hundred MPa to maintain integrity until bone regeneration completes.

Thus, the design philosophy centers on function-driven mechanical adaptabilityŌĆöreverse-engineering the material structure to provide ŌĆ£on-demandŌĆØ and ŌĆ£dynamically evolvingŌĆØ mechanical support according to anatomical site, repair timeline, and biomechanical microenvironment, maximizing aesthetic and functional restoration while ensuring clinical safety.

Figure 3: (a) StressŌĆōstrain curves [3]; (b) Cell mechanotransduction driven by surface mechanics [4]

4. Excellent Processability

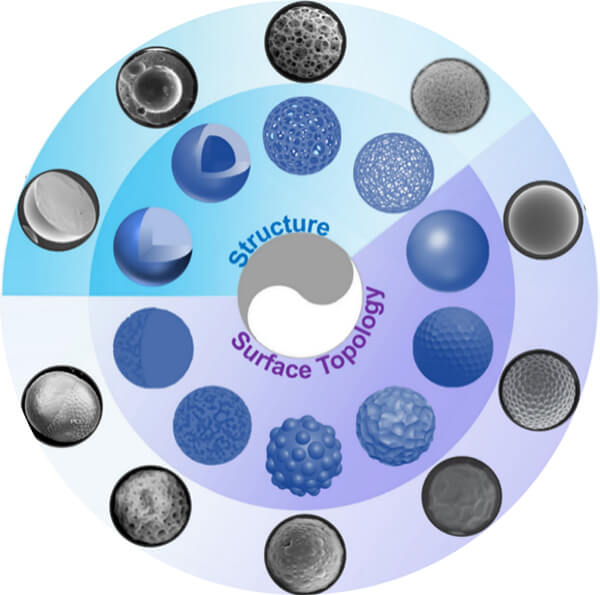

The superior processability of biodegradable polyesters allows flexible manufacturing across scalesŌĆöfrom nanofibers to centimeter-sized implantsŌĆöand compatibility with various advanced fabrication techniques.

This versatility opens vast design and innovation potential for regenerative medicine, drug delivery, and high-end aesthetic applications.

Figure 4: Representative structures and surface topologies of polyester microspheres [5]

III. Comparative Studies of Biodegradable Polyester Materials in Aesthetic Fillers

1. Comparison of Collagen Stimulation among Different Fillers

In regenerative aesthetic fillers, biodegradable polyester materials promote fibroblast proliferation and collagen (types I and III) synthesis, achieving tissue repair and anti-aging effects.

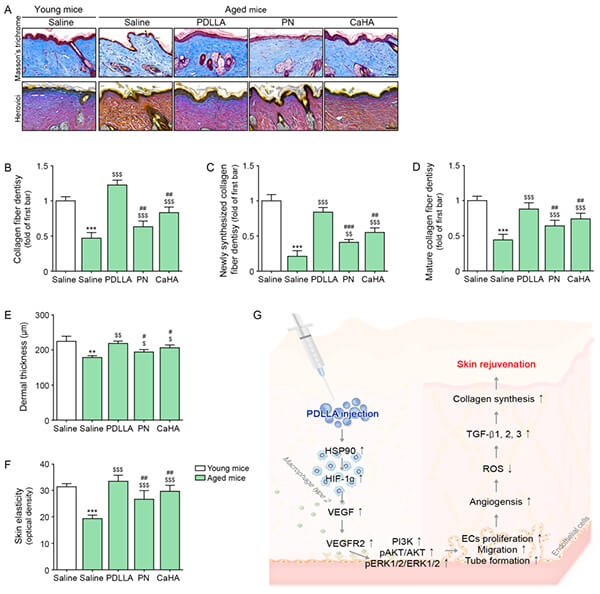

Comparative studies have shown that poly-D,L-lactic acid (PDLLA), polynucleotides (PN), and calcium hydroxyapatite (CaHA) enhance the expression of HSP90, HIF-1╬▒, and VEGF, thereby improving angiogenesis and collagen synthesis in aged skin.

As shown in Figure 5, PDLLA injection in aged mice resulted in the most significant increases in dermal collagen content, skin thickness, and elasticity [6].

Figure 5: Upregulation of collagen fibers in aged skin following PDLLA injection. (A) Masson trichrome and Herovici staining (scale = 100 ╬╝m); (BŌĆōD) Quantitative analysis of total, new, and mature collagen fibers; (E) Dermal thickness; (F) Skin elasticity [6]

2. Influence of Material Properties on Collagen Regeneration

Material characteristicsŌĆöincluding molecular weight, hydrophilicity, and degradation kineticsŌĆödirectly affect cellular behavior (especially fibroblasts) and the in vivo microenvironment, thereby determining collagen synthesis, organization, and maturation.

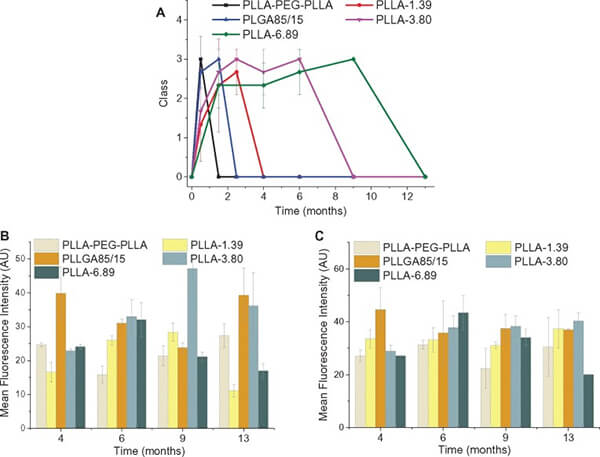

Animal studies comparing PLLA-PEG-PLLA, PLGA 85/15, and several PLLA formulations showed that:

- Faster degradation leads to more intense foreign-body and inflammatory responses, resulting in shorter collagen stimulation cycles;

- Slower degradation extends the duration of collagen regeneration [7].

Figure 6: (A) Average foreign-body reaction grades and semiquantitative analyses of type I (B) and type III (C) collagen regeneration induced by five filler materials [7]

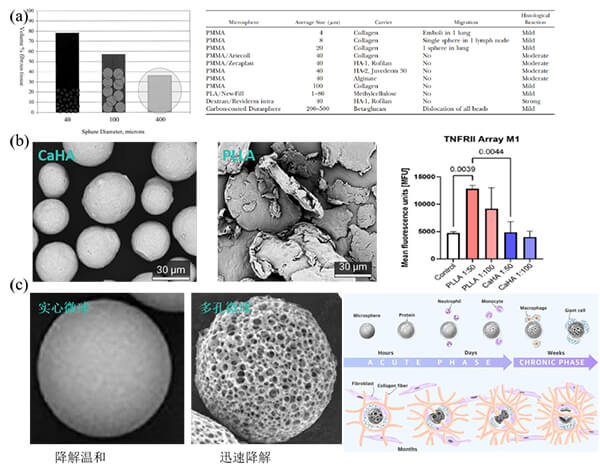

3. Effects of Microsphere Morphology on Filler Performance

The collagen-stimulating efficacy of biodegradable polyester microspheres arises from the combined effects of their chemical composition, physical morphology, and structural characteristics.

These features influence the foreign-body response and mechanical cues that ultimately govern the efficiency, longevity, and safety of collagen regeneration.

Key parameters include:

- Particle size, which affects macrophage responses and fibrotic encapsulation, thereby modulating regeneration cycles;

- Surface regularity, which influences the degree of inflammation;

- Degradation rate, which determines the duration of stimulation.

Figure 7: Effects of microsphere morphology on filler performance: (a) Particle size influences fibrotic encapsulation and histologic response [8]; (b) Comparison of inflammation after CaHA (Radiesse, Merz Aesthetics) vs. PLLA-SCA (Sculptra, Galderma) injection [9]; (c) Effects of morphology and porosity on filling outcomes [10]

IV. Innovative Applications: From Filling to Regeneration

Biodegradable polyester materials are propelling aesthetic fillers from simple ŌĆ£space-occupyingŌĆØ agents toward true regenerative stimulators.

Through polyester microspheres that induce endogenous collagen neogenesis, these materials achieve natural and long-lasting resultsŌĆöwhere the material gradually degrades as new collagen replaces it, creating progressively more natural outcomes.

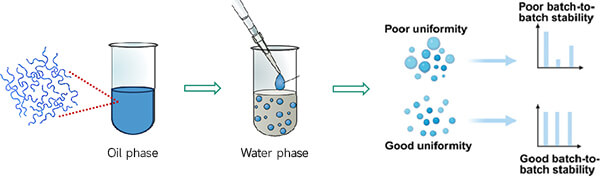

1. Principle of Polyester Microsphere Preparation

Microsphere fabrication involves thermodynamic and kinetic control over polymer behavior to produce spherical particles with diameters ranging from 1ŌĆō1000 ╬╝m.

Figure 8: Schematic of polyester microsphere fabrication principle

2. Common Preparation Methods

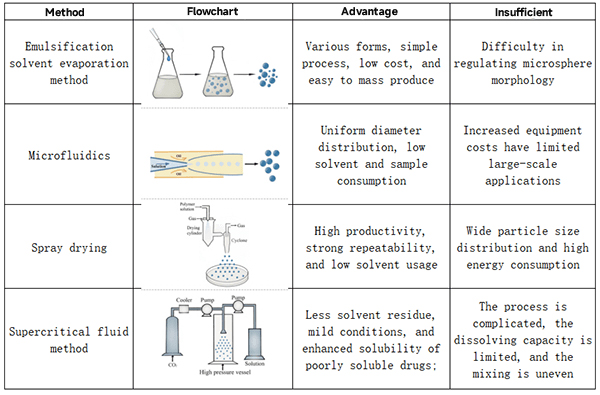

Typical microsphere fabrication techniques include:

(a) Emulsion method;

(b) Microfluidics;

(c) Spray drying;

(d) Supercritical fluid method.

Table 1: Common microsphere fabrication methods [11]

3. Innovative Applications of Polyester Microspheres

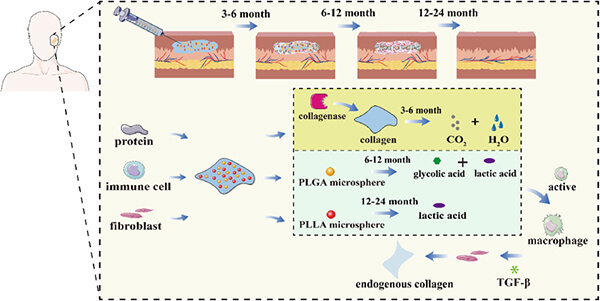

(1) Stimulative Regenerative Fillers with Designed Degradation Profiles

A novel PLLA/PLGA microsphereŌĆōcollagen composite achieves both immediate and sustained filling effects (Figure 9).

Collagen provides the early filling volume, while the PLGA microspheres stimulate early-stage collagen synthesis and PLLA microspheres sustain long-term collagen regeneration as they degrade [12].

Figure 9: Schematic of PLLA/PLGA microsphereŌĆōcollagen composite for continuous soft-tissue augmentation [12]

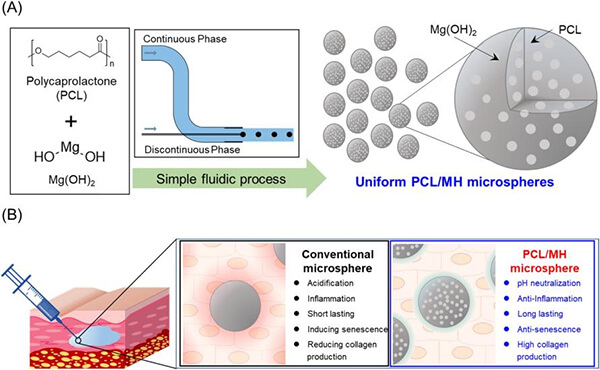

(2) Functional Composite Microsphere Fillers

A PCL/magnesium hydroxide (MH) composite microsphere system was developed in which MH neutralizes acidic degradation products, mitigating inflammation and slowing hydrolysis.

The released Mg┬▓Ōü║ ions inhibit senescence-related gene expression, prevent dermal aging, suppress collagenase activity, and maintain skin elasticity [13].

Figure 10: (A) Fabrication of PCL/MH microspheres; (B) Comparison between conventional PCL filler and developed PCL/MH functional filler [13]

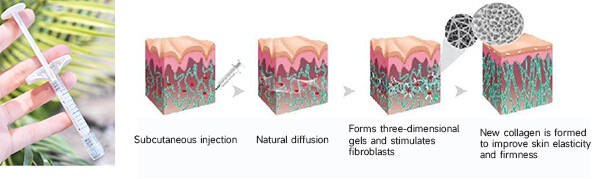

(3) Fully Liquid Biodegradable Regenerative Fillers

The Korean company Dexlevo has developed GOURI, a fully soluble (liquid) polycaprolactone (PCL) filler.

This material is a copolymer of hydrophobic and hydrophilic biocompatible polymers, heated above the polymerŌĆÖs melting point and stirred to produce a stable, aqueous dispersion containing nanoscale particles.

Upon injection, it remains uniformly distributed and induces tissue formation and repair, resulting in bioregenerative aesthetic effects [14].

Figure 11: Mechanism of action of GOURI [14]

Conclusion

Biodegradable polyester materials are ushering aesthetic fillers into a new eraŌĆötransforming them from simple volumizing agents into tools for tissue regeneration.

This evolution not only represents technological progress but also signifies a conceptual shift in aesthetic medicine:

from external modification to intrinsic regeneration,

from short-term enhancement to long-term sustainability,

and from isolated beauty to holistic health.

With continued research and technological advancement, biodegradable polyester materials are expected to deliver breakthrough products that make beauty more natural, safer, and longer-lasting.

The future has arrivedŌĆölet us anticipate the new possibilities and surprises that this field will bring.

References

[1] Li X, Yang Y, Zhang B, Lin X, Fu X, An Y, Zou Y, Wang JX, Wang Z, Yu T. Lactate metabolism in human health and disease. Signal Transduct Target Ther. 2022 Sep 1;7(1):305.

[2] Lindsay N. Woodard and Melissa A. Grunlan. ACS Macro Letters 2018, 7(8), 976ŌĆō982.

[3] Jorge Fern├Īndez, Agustin Etxeberria, Jose-Ramon Sarasua. Synthesis, structure and properties of poly(L-lactide-co-╬Ą-caprolactone) statistical copolymers. J Mech Behav Biomed Mater. 2012;9:100ŌĆō112.

[4] Qian Sun, Yong Hou, Zhiqin Chu, Qiang Wei. Soft overcomes the hard: Flexible materials adapt to cell adhesion to promote cell mechanotransduction. Bioact Mater. 2022;10:397ŌĆō404.

[5] Ze-Yu Wang et al. Natural biopolyester microspheres with diverse structures and surface topologies as micro-devices for biomedical applications. Smart Mater Med. 2023;4:15ŌĆō36.

[6] Oh S, Seo SB, Kim G, Batsukh S, Son KH, Byun K. Poly-D,L-lactic acid stimulates angiogenesis and collagen synthesis in aged animal skin. Int J Mol Sci. 2023;24(9):7986.

[7] Zhang Y, Liang H, Luo Q, Chen J, Zhao N, Gao W, Pu Y, He B, Xie J. In vivo inducing collagen regeneration of biodegradable polymer microspheres. Regen Biomater. 2021;8(5).

[8] Lemperle G, Morhenn VB, Pestonjamasp V, Gallo RL. Migration studies and histology of injectable microspheres of different sizes in mice. Plast Reconstr Surg. 2004;113(5):1380ŌĆō1390.

[9] McCarthy AD, Hartmann C, Durkin A, Shahriar S, Khalifian S, Xie J. A morphological analysis of calcium hydroxylapatite and poly-L-lactic acid biostimulator particles. Skin Res Technol. 2024;30(6).

[10] Lin C-Y et al. Efficacy and safety of poly-D,L-lactic acid microspheres as subdermal fillers in animals. Plast Aesthet Res. 2019.

[11] Xuebing Li, Luohuizi Li. Fabrication of polymeric microspheres for biomedical applications. Mater Horiz. 2024;11:2820ŌĆō2855.

[12] Xuan Li et al. Biodegradable PLLA/PLGA microspheres/collagen composites for continuous soft tissue augmentation. Compos Part B Eng. 2024;283:111603.

[13] Sang-Woo Shin et al. PCL microspheres containing magnesium hydroxide for dermal filler with enhanced physicochemical and biological performances. J Ind Eng Chem. 2019;80:854ŌĆō861.

[14] KR1020090130912 A.