From November 13 to 15, the 11th Symposium on Biobased and Biodegradable Materials Technology and Application & the 2025 Annual Meeting of the Degradable Plastics Professional Committee of the China Plastics Association was grandly held in Beijing.

At the conference, Chen Rui, Deputy General Manager of eSUN, was invited to deliver a presentation titled ŌĆ£Exploration and Reflections on Innovative Applications of Biodegradable Polyester Materials in High-end Medical Devices.ŌĆØ

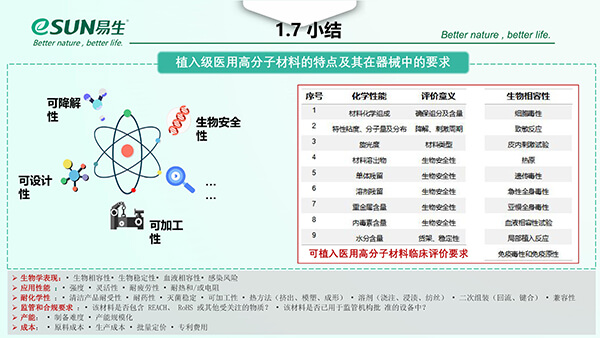

I. Performance Advantages of Biodegradable Polyester Materials

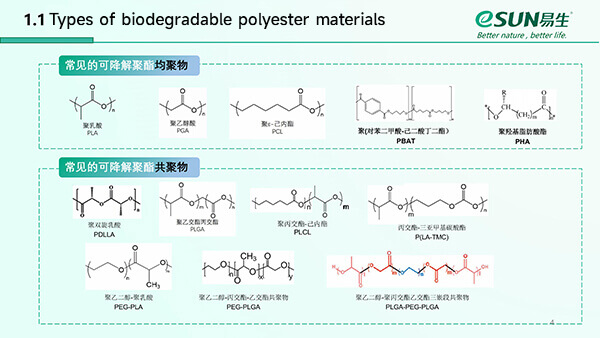

Biodegradable polyester materials, such as polylactic acid (PLA), polycaprolactone (PCL), and poly(lactic-co-glycolic acid) (PLGA), possess a series of outstanding characteristics:

1.Degradability

2.Biological Safety

3.Excellent Processability

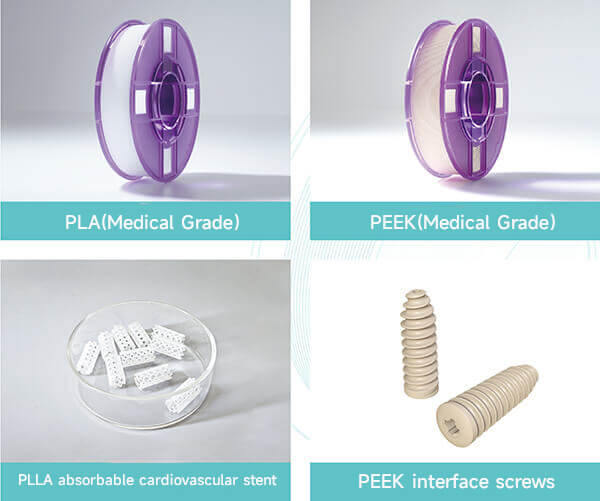

They can be processed into various profiles, including filaments, 3D printing filaments, tubes, microspheres, porous scaffolds, and can also be further processed into various device products.

4.High Designability

ŌæĀBy designing the types and ratios of comonomers, the degradation cycle, mechanical properties, and hydrophilicity/hydrophobicity of biodegradable polyester materials can be effectively regulated.

ŌæĪBy adjusting polymer molecular weight and distribution, end-group modification, block structures, branching, crosslinking, and hyperbranching, the performance of biodegradable materials can be effectively designed and tuned.

ŌæóBy controlling polymer orientation and crystallinity (aggregated-state structures), the degradation cycle and mechanical properties of biodegradable polyesters can be effectively regulated.

ŌæŻThrough blending and other approaches, heterogeneous morphologies can be designed to effectively regulate the performance of biodegradable polyesters.

ŌæżBy rationally designing monomer composition, polymer chain structure, condensed-state structure, and heterogeneous morphology, the performance of biodegradable polyester materials can be effectively regulated.

II. Applications of Biodegradable Polyester Materials in Implantable Devices

Due to their wide availability, high designability, easy processability, excellent mechanical properties, and biological safety, biodegradable polyester materials have been widely applied in the biomedical field, including cardiovascular interventional therapy, neurosurgery, plastic and maxillofacial surgery, otolaryngology, medical aesthetics, orthopedics/sports medicine, general surgery, oncology treatment, and regenerative medicine.

1.Interventional Therapy: Biodegradable coronary stents, biodegradable occluders, biodegradable flow-diverting stents, and biodegradable intravascular thrombosis filtration systems.

2.Neurosurgery: Absorbable cranial bone locks, absorbable dura mater, absorbable nerve repair conduits, biodegradable coils.

3.Plastic and Maxillofacial Surgery: Absorbable plate-and-screw systems.

4.Otolaryngology: Biodegradable sinus stents, absorbable Eustachian tube stents, absorbable guided tissue-repair membranes.

5.Medical Aesthetics: Injectable facial fillers, facial implantation threads.

6.Orthopedics: Absorbable interface screws, suture anchors, absorbable rib-fixation 7.rod-and-screw systems, absorbable bone plates, absorbable anterior spinal plating systems.

8.General Surgery: Absorbable hemostatic clips, absorbable anti-adhesion barrier membranes, absorbable lumen-to-lumen anastomosis systems.

9.Oncology Treatment: Drug-loaded tumor embolization microspheres, drug-loaded tumor sustained-release membranes.

Regenerative Medicine: Bone repair and regeneration, skin repair and regeneration, organ repair and regeneration.

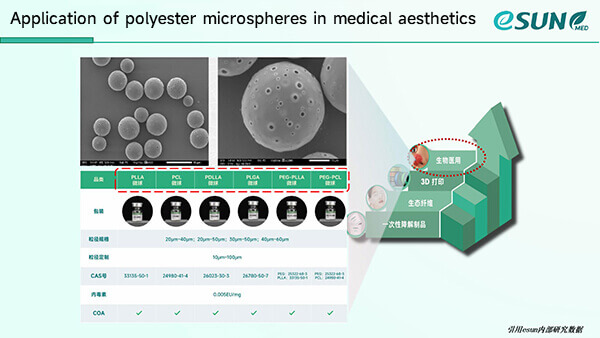

III. Application of Biodegradable Polyester Materials in High-end Medical Aesthetic Fillers

Biodegradable polyester materials are driving a shift in aesthetic fillers from simple ŌĆ£space occupationŌĆØ to ŌĆ£tissue regenerationŌĆØ:

Through polyester microspheres stimulating subcutaneous collagen neogenesis, they achieve natural and long-lasting filling effects. As the material degrades, newly formed endogenous collagen gradually replaces it, producing an increasingly natural outcome.

IV. Future Prospects for the Application of Biodegradable Polyester Materials in Medical Devices

3D printing technology can meet the requirements of personalized and high-precision device fabrication. By tapping into material functional characteristics, it will further drive functional iteration and performance breakthroughs in medical devices.

1. Biodegradable Polyester Materials + FDM 3D Printing ŌĆö Personalized Manufacturing for Medical Devices

In the field of medical implants, tissue-engineering scaffolds, cardiovascular stents, and bone fixation and repair materials (e.g., absorbable screws and absorbable plates) require patient-specific customization based on anatomical features. Conventional materials often have poor biocompatibility, and traditional processes are complex with long development cycles.

The personalized 3D printing medical solution based on new materials and new technologies enables:

- Direct generation of patient-specific models and implants based on CT/MRI data;

- Highly flexible structural design (porosity, gradient structures) that promotes cell growth, vascularization, and osseointegration;

- Production completed within hours to days from design to final product, significantly shortening surgical waiting time.

2. Biodegradable Polyester Materials + Photocuring 3D Printing ŌĆö Application in Orthotic Rehabilitation Shoes

eSUN has specially developed a dual-elastic thermo-photo-responsive resin that is compatible with LCD/DLP printers and enables high-performance, easy-to-print footwear materials with adjustable hardness.

On November 18, the one-component elastic resin 3D-printing integrated solution will be officially released.

The solution covers the entire workflowŌĆöfrom design, printing, and post-processing to final product deliveryŌĆöachieving seamless integration of materials, equipment, and post-processing. It addresses cost, efficiency, and quality challenges in flexible-elastic photocuring 3D printing. With one-piece 3D-printed shoes as a typical application, it builds a closed-loop supply chain and provides a new solution for the flexible-elastic manufacturing industry.

3. Biodegradable Polyester Materials + SLS 3D Printing Technology ŌĆö Injectable Facial Fillers and Facial Implantation Threads

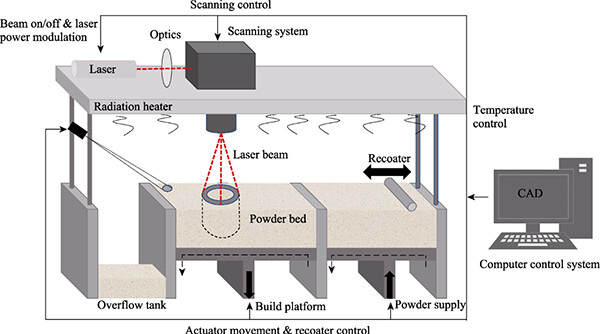

Selective Laser Sintering (SLS) is a powder-bed fusion additive manufacturing technology that uses a high-power laser beam to selectively sinter powder materials layer by layer.

It does not rely on molds, and its printing path is precisely controlled by digital models, making it ideal for rapid manufacturing of customized medical devices.

By tuning laser energy and scanning algorithms, the density and microporosity of formed parts can be controlled.

Moreover, unlike traditional FDM, SLS requires no support structures, making it suitable for producing complex structures with high porosity and multi-level gradients.